Tailor-made solutions to suit your application needs

The design and manufacture of various kinds of vacuum solutions is one of our core competencies. Besides offering proven standardised systems for common applications, we offer tailor-made solutions based on the customer’s unique requirements. End-to-end offing from concept, through design, manufacture and finally implementation

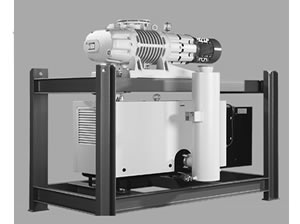

Fore Vacuum Pump Systems

oil-sealed

Usually RUTA vacuum systems are combinations of Roots vacuum pumps of the type WA, WS and RA or WAU and WSU with integrated bypass line with oil-sealed backing pumps for conventional generation of the vacuum. Single stage arrangements are capable of delivering pumping speeds of 250 to 16 000 m3/h (147 to 9424 cfm). Higher pumping speeds can be attained by paralleling several pumps. The attainable operating pressures depend on the number of pumping stages.

Fore Vacuum Pump Systems

Dry compressing

For increasing demands for example high requirements regarding cleanness when pumping high quality media which must not be contaminated by other media for recycling, often requires the use of universal pumps where the pump chamber is free of operating agents (dry pumps). Leybold Vacuum offers two solutions:

- Pump systems with dry compressing vacuum pumps combined with one or several Roots vacuum pumps.

- Single or multistage RUTA RAV vacuum pump systems, consisting of Roots vacuum pumps with pre-admission

High Vacuum Pump Systems

With oil sealed fore vacuum pumps

For generating a high or ultra high vacuum additionally to the high vacuum pump a backing vacuum pump is required. Oerlikon Leybold Vacuum offers complete ready-to-operate high vacuum pump systems of the PT series. The PT series is available as turn- key system or KIT version for do-it-yourself assembling. Depending on the process requirements the ultra high vacuum pumping systems are equipped with a oil lubricated or hydrocarbon free fore vacuum pump.

High Vacuum Pump Systems

With dry compressing fore vacuum pumps

The ultra high vacuum pump systems of the PT DRY series generate an absolutely hydrocarbon free vacuum. As high vacuum pump wide range turbomolecular pumps are used. This wide range pumps can achieve a better vacuum compared to conventional turbomolecular pumps so hydrocarbon free diaphragm or scroll pumps can be used as backing pump. The PT Dry series is a turn key ready-to-use vacuum system.

UNIVEX

Experimentation / Coating Systems

The UNIVEX multi-purpose experimentation systems were developed by Oerlikon Leybold Vacuum for applications in research and development, as well as for setting up pilot production systems. Their range of applications focuses chiefly on vacuum coating technology as well as vacuum process engineering experiments.